R&D: The Core of Dreamweldtech

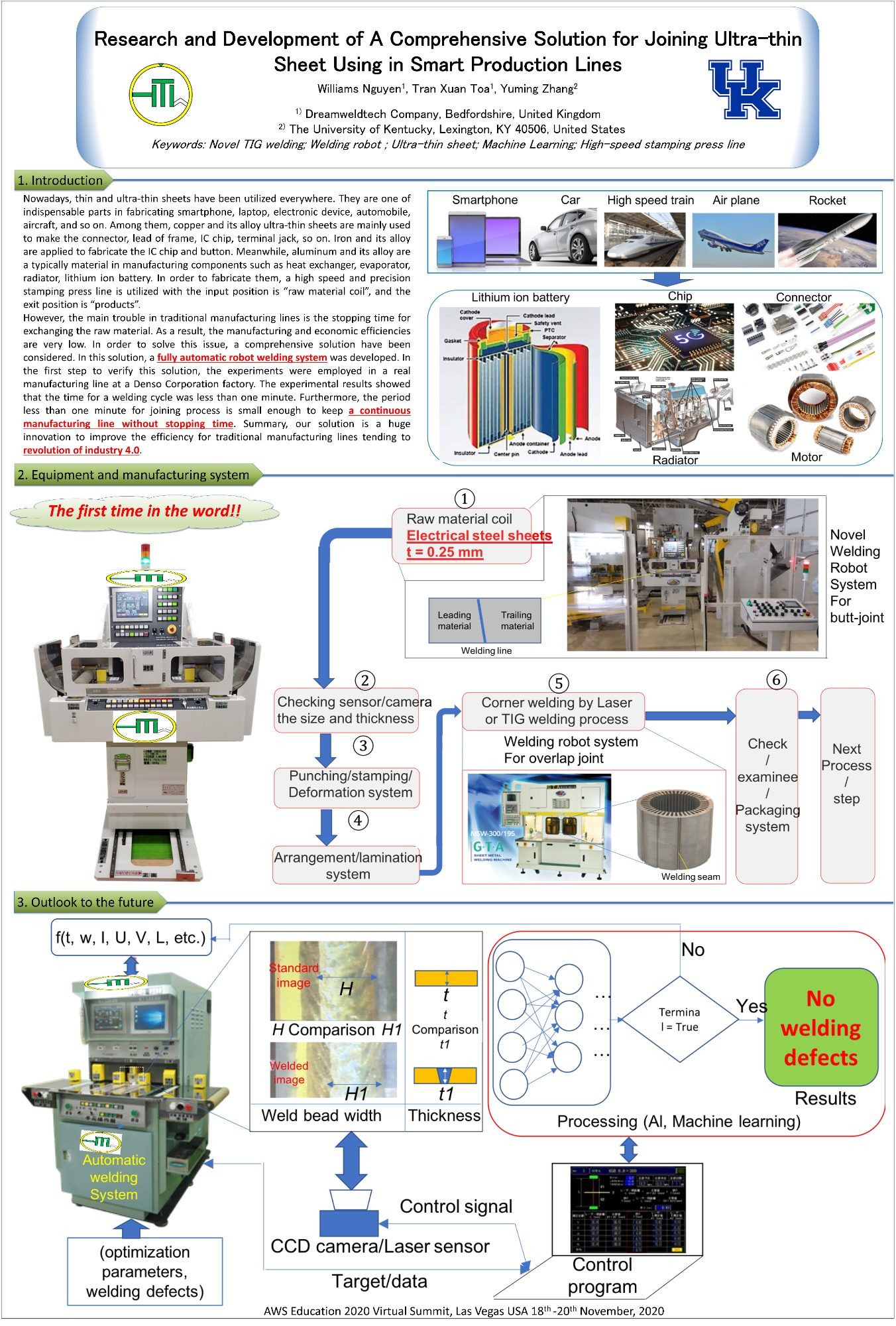

At Dreamweldtech, Research and Development (R&D) is the very essence of our existence. Our diverse team comprises experts with extensive backgrounds in welding, mechanics, mechatronics, IT, and business. Together, we are driven by a shared vision: to establish ourselves as a global leader in manufacturing welding robots and 3D mini-printing systems that pave the way for a sustainable society through the use of pioneering technologies, conceived and nurtured by our team.

Equipped for Innovation

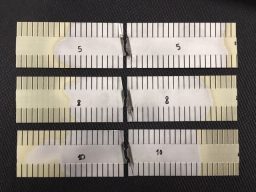

Equipped with state-of-the-art technology, our R&D efforts are backed by cutting-edge tools that span fundamental and applied research domains. Our arsenal includes a high-speed video camera, a laser illumination system, 2D and 3D flow software, thermal cameras, and more. These resources empower us to delve into the depths of innovation and push the boundaries of possibility.

From Inception to Reality

We take pride in our ability to drive innovation from its very inception. Our journey spans the full spectrum, from conceiving revolutionary ideas to crafting initial prototypes and finally culminating in fully-fledged commercial systems. This end-to-end approach underscores our commitment to delivering tangible solutions that make a real-world impact.

Global Footprint

With a robust presence across the globe, we operate a dedicated R&D factory in the UK, serving as the epicenter of our innovation efforts. Complementing this is our manufacturing facility in Vietnam, where our ideas take shape and become reality. Additionally, we maintain a sales office and a branch in the US, ensuring our innovations reach far and wide.

At Dreamweldtech, our mission is not just to innovate, but to transform industries and contribute to a more sustainable future. With a fusion of expertise, cutting-edge technology, and a commitment to excellence, we're pioneering the path to a brighter tomorrow.